| |

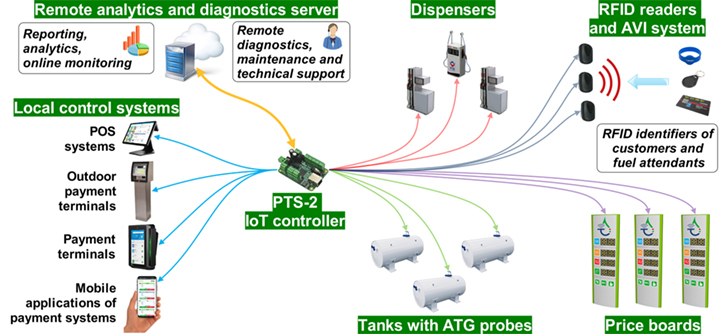

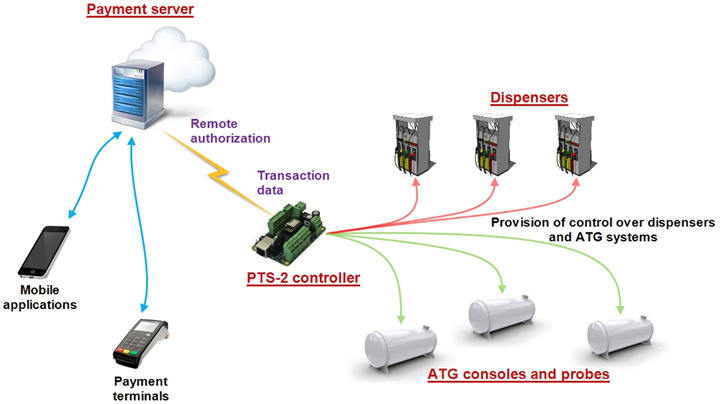

Forecourt controller PTS-2 is

a new controller designed for use at gas stations and fuel storage

facilities. It provides control over 100 brands of dispensers and 30

brands of ATG systems and probes using original communication protocols.

Use of the PTS-2 controller allows implementing of Internet of Things

(IoT) concepts as "Smart Dispenser", "Internet Dispenser", "Cloud Filling Station".

Using communication interfaces Ethernet, Wi-Fi and RS-232 PTS-2

controller provides ability to control forecourt equipment from

different control systems and with various configuration of hardware.  Click on image to enlarge Click on image to enlarge

PTS-2 forecourt controller for petrol stations serves

for control over petroleum, LPG and CNG dispensers and automatic tank

gauge systems and probes. It knows communication protocols of a great

variety of dispensers and ATG systems and console and allows control

over any of them in exactly the same way using its own input

communication protocols or popular pumps and ATG systems communication

protocols. POS systems, cash registers, payment terminals and mobile

applications thus can provide control over any of the dispensers on the

forecourt and should not matter what are the brands of dispensers and

ATG systems used – using PTS-2 controller they can provide control over

all of them in the same way, PTS-2 controller undertakes all work on

communication with dispensers and ATG systems using their native

communication protocols and takes into account all their peculiarities.

This completely simplifies work for a developer of control system: by

having implemented communication protocol of PTS-2 controller you gain

ability to provide control over any of dispensers and ATG systems

supported by PTS-2 controller in a single way. Thus, the time required

for development of POS system, cash register, payment terminal or mobile

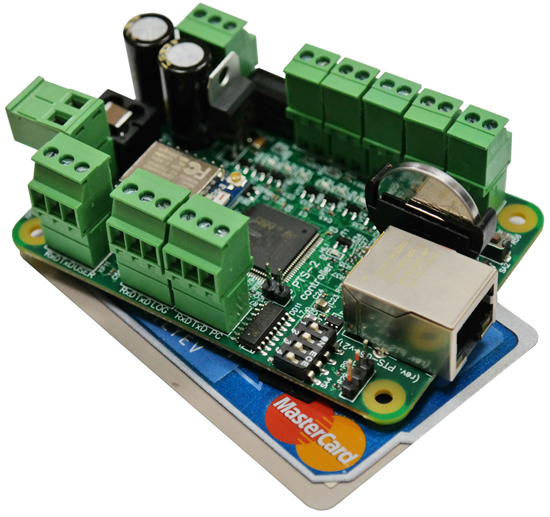

applications is significantly reduced. Features and benefits:- Credit card size for easy installation in any hardware

- Supports 100 brands of dispensers

- Supports 30 brands of ATG systems and probes

- SSL/TLS layers for secured communication

- Built-in web-server for monitoring, configuration, reporting and control

- Communication interfaces: RS-232, RS-485, Ethernet and Wi-Fi

- Rich set of interface converters

- Automatic operation with storage of sales to local database

- Automatic upload of data to remote server

- Rich API for integration by developers

- Android application for remote control

- Cost effective

Click on image to enlarge

PTS-2

controller provides rich API for easy integration with POS systems, OPT

terminals, cash registers, mobile and server applications and other

control systems for petrol stations. Simultaneous control over forecourt

equipment from several control systems connected to different

interfaces in PTS-2 controller.  Click on image to enlarge Click on image to enlarge

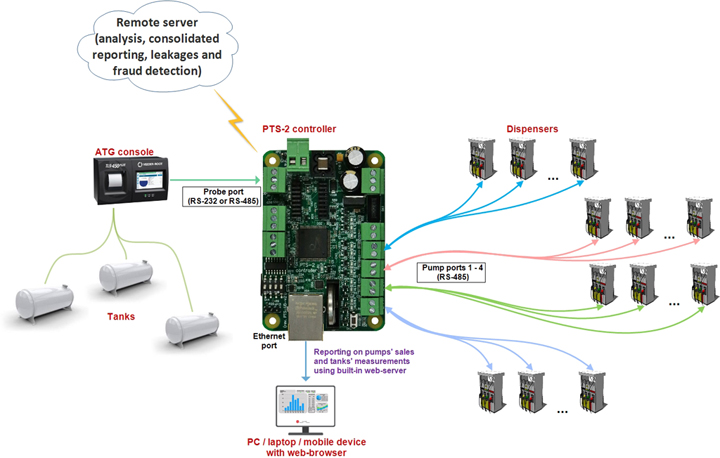

PTS-2 controller allows automatic operation over dispensers and ATG probes: - authorizes the dispensers automatically once nozzle is taken up and records all transactions into local database

- keeps control over tanks and records all changes in their remains into local database

- provides remote online monitoring over operations

- provides remote generation of reports

- exports

all sales and tanks measurements from local database to remote server,

where it is possible to generate reports on all sales remotely

Click on image to enlarge Click on image to enlarge

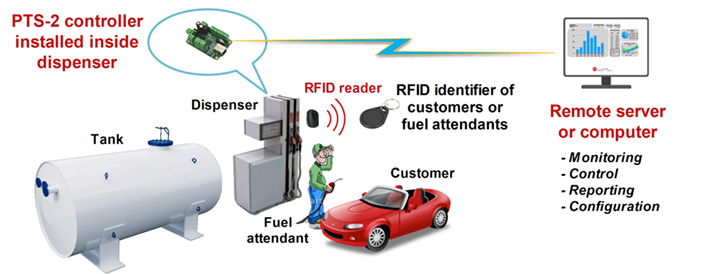

PTS-2

controller can be installed inside the dispensers and near ATG probes

and thus make them become IoT devices (Internet of Things) with easy

monitoring, control, configuration and reporting from any point

worldwide. Installation of PTS-2 controller inside the dispenser allows

to make a dispenser to be “Smart” or “Internet” dispenser. Control over

the dispenser becomes available through Wi-Fi, thus installation is

facilitated due to no need to place wired communication lines.  Click on image to enlarge Click on image to enlarge

PTS-2

controller has rich API for developers and can be easily integrated

with payment software systems, retail POS systems and ERP software.

PTS-2 controller pushes information on each performed transaction to

remote server, so server can get all data on sales immediately from

PTS-2 controller.  Click on image to enlarge Click on image to enlarge

PTS-2

controller can be installed inside the fuel tanker and thus make it

become IoT device (Internet of Things) with easy monitoring, control,

configuration and reporting from any point worldwide.  Click on image to enlarge Click on image to enlarge

- Supports over 70 communication protocols of

fuel dispensers and ATG systems. List of supported communication

protocols is constantly growing. Single firmware of PTS-2 controller

contains all available communication protocols for fuel dispensers and

ATG systems.

- Control up to 64 fuel dispenser sides (fueling places):

PTS-2 controller has 4 independent pump ports, each of them can be

configured to its own communication protocol and baud rate, thus PTS-2

controller provides communication with connected dispensers

simultaneously using up to 4 various communication protocols.

- Control up to 32 ATG probes (gauges):

PTS-2 controller has 3 independent probe ports, each of them can be

configured to its own communication protocol and baud rate, thus PTS-2

controller provides communication with connected probes simultaneously

using up to 3 various communication protocols.

- Credit-card size: suits to any dimensions for installation inside master systems.

- Support of 100 brands of fuel dispensers from various manufacturers:

2A, Actronic, Adast (Adamov Systems), Ag Walker, Agira, Angi

International, Ariel, Aspro, Assytech, Astron, Azt, Baransay, Batchen,

Bennett, Blue Sky, Censtar, CFT Clean Fuel, Compac, Coptron, Coritec,

Datian Machines, Dem G. Spyrides, Develco, Dong Hwa Prime, Durulsan,

Eaglestar, Emgaz Dragon, Epco, Esiwelma, Europump, Falcon LPG, Fornovo

Gas, Fuelquip, Fuelsis, Galileo, Gaslin, Gerkon, Gilbarco, Greenfield,

Hitachi, Hong Yang, IMW, Intermech, Kalvacha, Kievniigaz, Korea Ene,

KPG-2, Kraus, Kwangshin, Lanfeng, LG Ene, Logitron, Maser, Meksan /

Wayne SU86, Mekser, Mepsan, Midco, MM Petro (Zap), Motogaz, MS GAs,

Nara, Nuova Migas, Nuovo Pignone, PEC (Gallagher Fuel Systems),

Petposan, Petroequip, Petromeccanica, Petrotec, Prowalco, Pump Control,

Real-Tech, RIX, Safe, Salzkotten, Sanki, Sea Bird, Shelf, Scheidt &

Bachmann, Shibata, Slavutich, Somo Petro, Star, Tatsuno (Japan), Tatsuno

Europe (former Benc), Tekser, Tokheim, Tokheim India, Tokico, Tominaga,

Topaz, Transponder, Ucar Elektric, Unicon-TIT, Vanzetti, Wayne Dresser,

Wayne Pignone, Yenen, Zcheng Genuine Machines and others.

- Support of 30 types of automatic tank gauge (ATG) systems of various manufactures:

Accu, Alisonic, Assytech, Bluesky, Dut-E, Eaglestar, Ebw, Enraf,

Fafnir, Franklin Fueling, Gamicos, Gilbarco Veeder Root, Hectronic, Hong

Yang, Humanentec, Incon, Labko, Mts Atg Sensors, North Falcon,

Omnicomm, Omntec, Opw, Qingdao Guihe, Start Italiana, Struna, Uniprobe,

Vega, Windbell and others.

| PARAMETER | VALUE |

|---|

| Power supply voltage | 12 V DC | | Current consumption | 700 mA max | | Temperature range | from -40°C to +80°C | | Weight | 200 g | | Overall dimensions | 85 x 58 x 30 mm |

inquiry@newage-engineering.com

OR Call 24/7: 0321-2460858

|

|